Ventilatorenfabrik Oelde provides process fans with special wear protection before they leave the factory. The company will also repair parts which are liable to wear on fans of any make which are already in service.

Because of the processes involved, centrifugal fans in the cement industry handle dust-laden air and gases. Depending on the amount and type of dust, the various fan components are subject to increased wear. This applies particularly to raw mill fans downstream of the cyclone and to cement mill separator fans which are designed for dust loads up to 80 g/m³. Various by-pass fans and cooler exhaust air fans also number among the critical machines (Fig. 1).

Experts in individual solutions

Venti Oelde carries out research in cooperation with recognised institutes and universities to find optimum solutions for effective and cost-saving wear protection in handling the increasingly fine dust in the cement industry. As a result of Venti Oelde’s many years of experience as developer, manufacturer and supplier, their process fans fundamentally possess a special wear protection. This complies exactly with the specific application of the fan and fulfils the individual demands of the customer or plant operator.

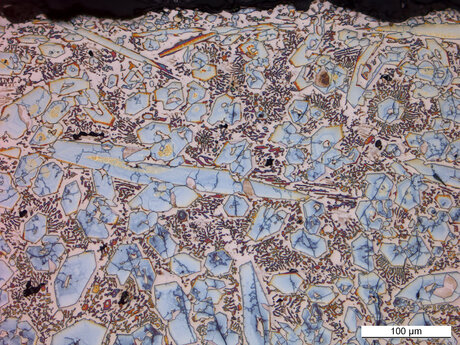

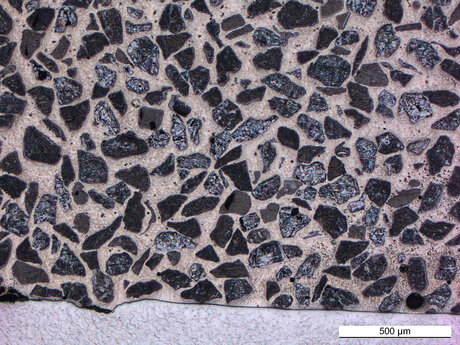

Meticulous planning of the wear protection is extremely important to ensure long and trouble-free fan operation. Venti Oelde, therefore, uses various qualities of manganese hard steel and chrome carbides (Fig. 2) as well as fused tungsten carbides (Fig. 3) with different base materials as wear protection. In addition to their own fans, Venti Oelde also advises their customers on wear protection for fans made by other manufacturers.

Repairs in modular system

Even with the best wear protection, the critical areas on the rotors of centrifugal process fans must be regularly checked after a period of service. If necessary, the worn areas of the rotor must be re-hardfaced.

For this, Venti Oelde offers, as well as conventional wear protection, a sort of modular system. This includes in particular six modules:

Wrap-around edge protection liners for blade inlet edges

Wear plates on blade inlet edge

Wear strips for the impeller centreplate

Wear plates for the blades

Wear plates for impeller shroud protection

Protective caps and plates for the threaded connections impeller – shaft (Fig. 4)

These modular products make it possible to adapt protective measures specifically to the wear pattern on the rotor and, therefore, quickly and cost-effectively to carry out either repairs or upgrading. Venti Oelde carries out these selective repairs in its work or on site. When Venti Oelde specialists have given advice and instructions, it is often possible for the operator to carry out the repairs himself. If requested, Venti Oelde will also provide filler metal, welding material and welding instructions for the repair of radial fan impellers and rotors (Fig. 5).

The Venti Oelde modular system makes it possible to use wear protective materials of varying quality in the different areas, depending on the load. The particularly endangered areas have been marked in colour.