Author: Joachim Schürmann, Ventilatorenfabrik Oelde GmbH

Ventilatorenfabrik Oelde GmbH has succeeded in ensuring the highest possible availability of centrifugal fans in operation in large plants, simultaneously keeping investment costs low and providing full capacity utilization.

A large plant is only made profitable by high capacity and – extremely important – continuous availability, combined with low investment and maintenance costs. The ever larger plant components make it, however, ever more difficult to ensure reliability and availability. Particularly centrifugal fans make high technical demands on plant constructors.

High Availablity

Venti Oelde responds to these demands with a so-called tandem drive, while ensuring compliance with various implementation rules of the API (American Petroleum Institute) as well as any additional customer requirements. Particularly when building new plants is this of economic interest. After all, production loss in a large plant can result in losses amounting to several hundred thousand Euros daily.

An alternative would be the parallel operation of two production lines. The damage caused by the loss of one production line would be limited by the availability of the second line. However, this would mean considerable additional costs in investment, maintenance and servicing.

The Tandem Drive

A tandem drive for centrifugal fans comprises two drives: a medium or high voltage motor and a steam driven turbine.

The medium or high voltage motor serves to start up the centrifugal fan, since steam from the boiler houses may not be available at the start-up of the plant. As soon as sufficient steam is available, the plant switches to the steam turbine. This is an advantage because in many plants steam is produced in large quantities, e.g. from the operation of heat exchangers. A further advantage is that in those locations where the power supply is unreliable, the steam turbine as a second drive represents a welcome alternative.

Changing Drive Automatically

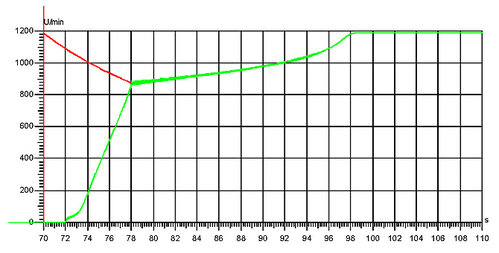

Venti Oelde can switch over automatically, without interrupting the production process from one drive to the other. Switching from the electric motor to the steam turbine is unspectacular. The steam turbine can be brought up to the rated speed of the motor through the speed regulation. When a defined differential speed between the two drives has been reached, the turbine takes over and the electric motor can be switched off. The electric motor is removed from the shaft unit via the overrunning one-way clutch.

The reverse, switching from turbine drive to the electric motor is, however, technically sophisticated. It is true that relatively simple frequency-controlled motors could be used for medium- and high voltage, these are, however, very cost-intensive. Venti Oelde, therefore, uses the considerably more favourable version of motors with direct on-line starting. In this case, Venti Oelde uses a special coupling configuration which limits the torque peaks to a defined, maximum permissible torque. This rules out damage to the drive and shaft assembly.

Because: When the steam turbine trips, the direct on-line starting electric motor undergoes an extreme acceleration as a result of the load-free running-up. At the moment „X“ the electric motor encounters the fan rotor, which has been released by the trip and is decelerating, and accelerates it up to rated speed.

Safety right down the line

By designing centrifugal fans with two energetically independent drives, Venti Oelde makes it possible to carry out maintenance work on the drive which is not in service while the plant is in operation. Overrunning one-way clutches, among other things, are used for this purpose to ensure reliable operation. The numerous design regulations for centrifugal fans and their individual components in accordance with standards such as API 614, API 670, API 671 or API 673 are met by Venti Oelde for couplings, oil systems and machine monitoring systems as well as for instrumentation, control valves, manometers, etc.

Successful in Theory and Practice

Venti Oelde's design concept has proved itself to be successful on a daily basis in large plants worldwide with safe and cost-effective operation. Extensive test runs and simulations of a wide variety of operating conditions prove that centrifugal made by Venti oelde also meet the specific customer requirements.

| Technical Data | |

| Operating flow volume | 927.000 Am³/h |

| Differential pressure | 8800 Pa |

| Mechanical design | 350 °C |

| Drives | 3300 kW |

| Rotating speed | 1192 rpm |

Process Description

Typical processes where combustion air and flue gas fans with tandem drive are used are ammonia, methanol, hydrogen and syngas plants. A hydrogen/steam mixture is converted into a mixture of H2, CO and CO2 and a remainder of CH4 using a steam reformer.

The overall reaction in the steam reformer is strongly endothermic and thus requires heat input. The necessary reaction heat is provided by burners which are arranged in the furnace ceiling between the tube rows.

A combustion air fan must supply the required combustion air to the steam reformer burner. The flow volume necessary for the combustion air can, depending on the size of the plant, be up to 550.000 Am³/h betragen.

Downstream of the combustion air fan, the combustion air is preheated to the required temperature by the burners. Combustion air is added in excess of the stoichiometric requirements to ensure complete combustion. The released heat is mainly transferred to the process in the reformer tubes, while the waste heat is carried with the flue gas at about

1050 °C to a horizontal heat exchanger.

The waste heat is utilized in the convection bank as far as possible, for example:

generating and super-heating steam

preheating the hydrocarbon/steam mixture for the steam reformer

preheating and evaporating process condensate

preheating the hydrocarbon feed

preheating the combustion air

Finally, the flue gas is exhausted through the stack to the atmosphere by means of a flue gas fan. The flue gas flow volume can be as much as 1.000.000 Am³/h betragen.

关注万迪欧德公众号

万迪欧德抖音号

Copyright © 2022-2023 Venti Oelde (Jiangsu) Air Handling Equipment Co. Ltd All Right

备案号:ICP 2023002554 技术支持:镁诚科技